Technicial Specifications

| Power - Net | 66 kW |

| Maximum Torque - 1,400 rpm | 394 N·m |

| Net Power - 2,200 rpm - ISO 9249 | 66 kW |

| Torque Rise - 1,200 rpm - Net | 38% |

| Rated Power (Standard) - 2,200 rpm - Gross - ISO 14396 | 68.5 kW |

| Displacement | 4.4 l |

| Note (2) | No derating required up to 2286 m altitude. Auto derate protects hydraulic and transmission systems. |

| Model | Cat 3054C Mechanical Turbocharged |

| Note (1) | Net power advertised is the power available at the flywheel when the engine is equipped with fan, air cleaner, muffler and alternator. |

| Emissions | Emissions equivalent to EU Stage II. |

| Bore | 105 mm |

| Stroke | 127 mm |

| Operating Weight - Nominal | 8425 kg |

| Operating Weight - Maximum | 11000 kg |

| Operating Weight | 8425 kg |

| Counterweights - Medium | 240 kg |

| Operating Weight - ROPS Capacity - Maximum | 11000 kg |

| Note | *Machine Configuration – standard engine, standard stick hoe, standard cab with A/C, AWD standard shift transmission, 0.96 m3 MP loader bucket, 24 inch standard duty hoe bucket, 12.5/80-18 and 16.9-28 tires, no counterweight, 80 kg operator and full fuel tank. |

| Operating Weight - Estimated | 8425 kg |

| Counterweights - Base | 115 kg |

| Minimum Counterweight Recommendations - E-Stick: E-Stick | 210 kg |

| Minimum Counterweight Recommendations - E-Stick: Loader Bucket - GP | 530 kg |

| Counterweights - High | 460 kg |

| Minimum Counterweight Recommendations - E-Stick: Loader Bucket - MP | 681 kg |

| Minimum Counterweight Recommendations - E-Stick: Loader Bucket - MP with Fork Brackets | 691 kg |

| System Pressure - Backhoe | 250 bar |

| System Pressure - Loader | 250 bar |

| Maximum Pump Capacity | 132 l/min |

| Type | Closed Center |

| Pump Type | Variable Flow, Axial Piston |

| Turning Circle (inner wheel not braked) - Outside Front Wheels | 8.18 m |

| AWD Cylinder, One (1) Double Acting - Rod Diameter | 36 mm |

| Turning Circle (inner wheel not braked) - Outside Widest Loader Bucket | 10.97 m |

| AWD Cylinder, One (1) Double Acting - Stroke | 120 mm |

| AWD Cylinder, One (1) Double Acting - Bore | 65 mm |

| Type | Front Wheel |

| Power Steering | Hydrostatic |

| Hydraulic Tank | 40 l |

| Rear Axle - Planetaries | 1.7 l |

| Cooling System | 22 l |

| Transmission - Power Shuttle - AWD | 15 l |

| Fuel Tank | 160 l |

| Front Axle (AWD) | 11 l |

| Engine Oil - With Filter | 8.8 l |

| Rear Axle | 16.5 l |

| Hydraulic System | 106 l |

| Front Axle (AWD) - Planetaries | 0.7 l |

| Power Shuttle Transmission - Forward 2nd | 9.3 km/h |

| Power Shuttle Transmission - Forward 4th | 40 km/h |

| Power Shuttle Transmission - Forward 1st | 5.6 km/h |

| Power Shuttle Transmission - Forward 3rd | 21 km/h |

| Power Shuttle Transmission - Reverse 3rd | 21 km/h |

| Power Shuttle Transmission - Reverse 1st | 5.6 km/h |

| Power Shuttle Transmission - Reverse 2nd | 9.3 km/h |

| Note | Travel speeds of Four Wheel Drive backhoe loader at full throttle, when equipped with 16.9×28 rear tires. |

| Power Shuttle Transmission - Reverse 4th | 40 km/h |

| Features (1) | Heavy-duty rear axle with self adjusting inboard brakes, differential lock and final drives. |

| Features (3) | AWD front axle is pendulum mounted and permanently sealed and lubricated, requiring no daily maintenance. Also features double-acting steering cylinder with 52° steering angle for increased maneuverability. |

| Features (2) | AWD is engaged by front console panel switch or by brake pedal during all-wheel-braking operation. AWD can be engaged on the move, under load, in any gear, forward or reverse. AWD has outer final drives for easy maintenance. |

| Type | Fully enclosed boosted, hydraulic, multiple discs. |

| Features (6) | Meets ISO 3450:2011 and Central Motor Vehicles Rules requirements. |

| Features (2) | Completely enclosed and sealed. |

| Features (5) | Parking/secondary brakes are independent of the service brake system. Parking (secondary) brake is mechanically applied through a hand lever located in the right side console. |

| Features (3) | Self-adjusting. |

| Features (1) | Inboard oil-immersed, hydraulically actuated multiple Kevlar discs on final drive input shaft. |

| Features (4) | Dual foot-operated boosted brake pedals can be interlocked for roading. |

| Loading Reach | 1648 mm |

| Loading Height | 3947 mm |

| Digging Depth, 600 mm Flat Bottom | 4158 mm |

| Maximum Operating Height | 5722 mm |

| Stick Dig Force | 33.66 kN |

| Digging Depth, Manufacturer's Maximum | 4756 mm |

| Reach from Swing Pivot at Ground Line | 5657 mm |

| Bucket Dig Force | 56.61 kN |

| Digging Depth, 600 mm Flat Bottom, Manufacturer's | 4719 mm |

| Digging Depth, 2440 mm Flat Bottom | 3806 mm |

| Digging Depth, SAE Maximum | 4191 mm |

| Stabilizer Overall Width | 2242 mm |

| Swing Arc | 180° |

| Bucket Rotation | 205° |

| Grill to Bucket Cutting Edge, Carry Position | 1449 mm |

| Tipping Load at Breakout Point | 6048 kg |

| Maximum Operating Height | 4832 mm |

| Lift Breakout Force | 51.04 kN |

| Dump Reach at Maximum Angle | 822 mm |

| Capacity | 1 m³ |

| Width | 2262 mm |

| Digging Depth | 145 mm |

| Dump Height at Maximum Angle | 2766 mm |

| Dump Angle at Full Height | 46 ° |

| Lift Capacity at Maximum Height | 3172 kg |

| Maximum Hinge Pin Height | 3449 mm |

| Maximum Bucket Rollback at Ground Level | 40° |

| Tilt Breakout Force | 59.26 kN |

| Maximum Grading Angle | 116° |

| Overall Transportation Height - 4.3 m | 3757 mm |

| Wheelbase AWD | 2200 mm |

| Height to Top of Cab/Canopy | 2895 mm |

| Overall Width | 2346 mm |

| Overall Length in Roading Position | 5674 mm |

| Height to Top of Exhaust Stack | 2716 mm |

| Overall Transportation Length | 5681 mm |

| Rear Axle Centerline to Front Grill | 2708 mm |

| Note | Dimensions and performance specifications shown are for machines equipped with 12.5/80-18 front tires, 16.9-28 rear tires, standard cab, standard stick with 610 mm standard duty bucket, and 1.05 m³ GP loader bucket and standard equipment unless otherwise specified. |

| Net Power Rating at 2,200 rpm | 66 kW |

| Gross Power ISO 14396 | 68.5 kW |

| Maximum Operating Height | 6338 mm |

| Reach from Swing Pivot at Ground Line | 6585 mm |

| Stabilizer Overall Width | 2242 mm |

| Digging Depth, Manufacturer's Maximum | 5697 mm |

| Swing Arc | 180° |

| Bucket Dig Force | 56.61 kN |

| Digging Depth, SAE Maximum | 5208 mm |

| Loading Height | 4491 mm |

| Digging Depth, 2440 mm Flat Bottom | 4887 mm |

| Loading Reach | 2546 mm |

| Digging Depth, 600 mm Flat Bottom, Manufacturer's | 5684 mm |

| Stick Dig Force | 24.59 kN |

| Bucket Rotation | 205° |

| Digging Depth, 600 mm Flat Bottom | 5168 mm |

| Digging Depth, Manufacturer's Maximum | 4707 mm |

| Digging Depth, 600 mm Flat Bottom, Manufacturer's | 4668 mm |

| Loading Height | 3934 mm |

| Stabilizer Overall Width | 2242 mm |

| Digging Depth, 2440 mm Flat Bottom | 3740 mm |

| Bucket Dig Force | 57.22 kN |

| Digging Depth, SAE Maximum | 4116 mm |

| Reach from Swing Pivot at Ground Line | 5603 mm |

| Stick Dig Force | 35.3 kN |

| Swing Arc | 180° |

| Digging Depth, 600 mm Flat Bottom | 4092 mm |

| Loading Reach | 1528 mm |

| Maximum Operating Height | 5721 mm |

| Bucket Rotation | 205° |

| Dig Depth | 4707 mm |

| E-Stick Retracted | 4756 mm |

| E-Stick Extended | 5697 mm |

| Inside Cab | 80 dB(A) |

| Outside Cab | 104 dB(A) |

| Width | 2262 mm |

| Dump Reach at Maximum Angle | 897 mm |

| Digging Depth | 112 mm |

| Lift Breakout Force | 54.48 kN |

| Maximum Bucket Rollback at Ground Level | 41° |

| Dump Height at Maximum Angle | 2735 mm |

| Dump Angle at Full Height | 46° |

| Maximum Hinge Pin Height | 3449 mm |

| Grill to Bucket Cutting Edge, Carry Position | 1480 mm |

| Tipping Load - Breakout Point | 6225 kg |

| Lift Capacity at Maximum Height | 3630 kg |

| Tilt Breakout Force | 53.91 kN |

| Maximum Operating Height | 4370 mm |

| Capacity | 1.05 m³ |

| Maximum Grading Angle | 113° |

| Dump Reach at Maximum Angle | 822 mm |

| Tipping Load at Breakout Point | 6301 kg |

| Tilt Breakout Force | 60.47 kN |

| Lift Capacity at Maximum Height | 3496 kg |

| Lift Breakout Force | 53.95 kN |

| Maximum Bucket Rollback at Ground Level | 42° |

| Digging Depth | 145 mm |

| Dump Height at Maximum Angle | 2766 mm |

| Grill to Bucket Cutting Edge, Carry Position | 1449 mm |

| Maximum Hinge Pin Height | 3449 mm |

| Maximum Operating Height | 4348 mm |

| Capacity | 1 m³ |

| Width | 2262 mm |

| Dump Angle at Full Height | 46° |

| Maximum Grading Angle | 116° |

| Overall Width | 2346 mm |

| Overall Transportation Length | 5681 mm |

| Overall Length in Roading Position | 5674 mm |

| Height to Top of Exhaust Stack | 2716 mm |

| Height to Top of Cab/Canopy | 2895 mm |

| Note | Dimensions and performance specifications shown are for machines equipped with 12.5/80-18 front tires, 16.9-28 rear tires, standard cab, standard stick with 610 mm standard duty bucket, and 1.05 m³ GP loader bucket and standard equipment unless otherwise specified. |

| Rear Axle Centerline to Front Grill | 2708 mm |

| Overall Transportation Height - 4.3 m | 3757 mm |

| Wheelbase AWD | 2200 mm |

| Rear Axle - Static | 22964 kg |

| Front Axle (AWD) - Dynamic | 9186 kg |

| Rear Axle - Dynamic | 9186 kg |

| Front Axle (AWD) - Static | 22964 kg |

| Height to Top of Exhaust Stack | 2716 mm |

| Wheelbase AWD | 2200 mm |

| Overall Transportation Height - 4.3 m | 3757 mm |

| Note | Dimensions and performance specifications shown are for machines equipped with 12.5/80-18 front tires, 16.9-28 rear tires, standard cab, standard stick with 610 mm standard duty bucket, and 1.05 m³ GP loader bucket and standard equipment unless otherwise specified. |

| Overall Transportation Length | 5677 mm |

| Overall Length in Roading Position | 5725 mm |

| Overall Width | 2346 mm |

| Height to Top of Cab/Canopy | 2895 mm |

| Rear Axle Centerline to Front Grill | 2708 mm |

Advantages and Features

Operator Station – Everyone can get comfortable in this cab.

All Day Comfort

The all new 426F2 cab is designed to provide maximum comfort, ease of operation and overall style for today’s demanding operator. The new design features a spacious interior, flat glass and excellent visibility. The cab is wider allowing the operator to freely move when turning from one mode of operation to another. Excellent ergonomics ensure that all controls are within easy reach of the operator, with tilt steering column now available as an option. Other features include additional storage space, large vents throughout the cab and clear gauges that provide information to the operator to help maximize the machine’s performance. Tinted glass is offered as standard.

Power Train – Powerful performance.

Power Train

The 426F2 features the Cat 3054C engine. The engine is a four cylinder, four stroke direct injection turbo, equipped with standard glow plug starting for optimal cold weather performance. This provides reliable starting performance down to –26° C. An optional cold weather pack is available giving reliable starting performance down to –55° C. The engine also features a gear driven water pump, providing better reliability than conventional belt driven technology.

Axle and Brakes

The 426F2 rear axle is an enclosed design with a wet multi-plate braking system. The system is oil immersed and self-adjusting, and allows operation in the harshest environments. The rear axle offers 100% Diff-Lock giving increased traction when working on poor ground conditions. This gives increased performance with less wear and tear to tires. The system has dual brake pedals for split braking in confined working spaces. The All Wheel Drive (AWD) is engaged via a front console panel switch or by the brake pedal during all-wheel-braking operation. The AWD can be engaged on the move, under load, in any gear and in forward or reverse. The AWD front axle is pendulum mounted and permanently sealed and lubricated, requiring no daily maintenance. A guard is available to protect the drive shaft increasing the durability of this machine when working in hard rocky environments.

Transmission

The 426F2 comes equipped with a 40 km/h Power-Shuttle transmission, improving roading speed and providing better spacing between gear ratios. The forward/reverse lever on the steering column is placed for easy directional changes on the move, and the gear selection is from a floor mounted shift lever.

Loader Performance – Parallel lift and superior breakout forces.

Parallel Lift

The 426F2 parallel lift loader boasts class leading lift capacities and breakout forces, providing more power and greater productivity. Available with General Purpose Bucket, Multi Purpose Bucket, or Multi Purpose Bucket with Fork Brackets, the 426F2 can be matched precisely to your needs. The proven design of the F2 loader makes light work of lifting and loading. The parallel lift loader arms offer excellent forward visibility along with outstanding material retention throughout the lift and lower cycles.

Ride control option offers loader suspension to improve ride comfort when moving around the job site or roading the machine. There is also the added benefit of increased material retention providing an invaluable boost in productivity.

Backhoe Performance – Versatile design for any application.

Excavator Style Boom

Caterpillar’s instantly recognizable boom is more than a cosmetic design feature, it also outperforms straight boom designs too. Whether close-up truck loading on a narrow highway or digging over obstacles such as walls, the excavator style boom outperforms the rest. Combine this versatility with powerful breakout forces and the controllability of the load-sensing, flow sharing hydraulic system and you have the best boom and stick combination in the industry. The boom is a narrow design, ensuring maximum visibility to the work tool and ground. Additionally, our system offers swing and boom cushioning as standard. This feature enables very fast trenching by damping the boom on lift. Swing cushioning enables easy spotting of the hoe over the trench.

Extendible Stick

The 426F2 is available with an extendible stick that increase dig depth and reach capability increasing the machines versatility and utilization, reducing the amount of time spent repositioning the machine. A sliding inner section design helps to ensure the wear pads remain as dirt free as possible, extending adjustment and replacement intervals. One-Way or Two-Way lines, for operating hydraulic work tools, are available with the E-Stick and have been routed so that they are protected from damage when working in the narrowest of trenches.

Powerful and Efficient Hydraulics – Load-sensing system delivers improved fuel economy.

Hydraulic Performance

It’s rare that you’ll be working at full production 100% of the time, so why should the machine be working at full capacity, using more fuel, making more noise and generally increasing wear and tear on key components? The 426F2 has a load-sensing, closed center hydraulic system, which is designed to closely match power and flow to the demand needed by the operation. This works to both increase fuel efficiency and decrease wear and tear.

So whether you’re in full trenching mode, or delicately digging around services, you are always in total control. In applications such as loading and carrying, speed is important. The system will match the flow needed to get the job done quickly and efficiently. As there is minimal demand on the system unless needed, there are less parasitic horsepower losses and more power available for rimpull which means better loading and roading performance.

The 426F2 also features flow-sharing hydraulic valves, ensuring that the correct flow of oil reaches the implement cylinders, providing greater control and eliminating oil starvation when operating multiple functions, such as grading with the backhoe.

Serviceability – Easy service to keep your machine working.

Easy Access

Daily checks that can be time consuming for a busy operator are kept to a minimum on the 426F2. The 426F2 is equipped with a flip open hood, allowing access to all the check and fill points, air cleaner, washer bottle and visual check indicators. The 426F2 offers a clear bowl precleaner, designed especially for the tough environments that this machine operates in giving extra protection to the engine. This is located on top of the hood and gives a visual indicator to the operator that it needs to be emptied. The hinged cooling pack provides easy access to not only the radiator and air conditioner, but also the transmission and hydraulic cooler. The 426F2 carries on the Cat Backhoe Loader tradition with sealed for life axle oscillating pins, axle and driveshaft U-joints. Cat Product Link™ system provides remote reporting of machine location and hours.

Customer Support – Unrivaled customer support network.

Renowned Cat Dealer Support

From helping you choose the right machine to knowledgeable ongoing support, Cat dealers provide the best in sales and service.

- Preventive maintenance programs and guaranteed maintenance contracts

- Best-in-class parts availability

- Operator training to help boost your profits

- Genuine Cat Remanufactured parts

Customer Support Agreements

Your Cat dealer can offer a comprehensive range of Customer Support Agreements (CSA) that can be individually tailored to suit your finances and requirements. Dealers can offer a range of options from a full preventive maintenance with S•O•SSM package to a parts only CSA. Protect your valuable investment and know exactly what your monthly payments will be to help you run your business.

Machine Selection

Your dealer can help you with your machine purchase decision, based on your requirements and help keep operating costs to a minimum. Is the machine you have in mind exactly the best for your job or could there be a more suitable solution?

Training and Support

Speak to your dealer about additional support. They can advise you on operating techniques for your machine that will minimize wear and tear, maximize productivity, lower owning and operating costs and help you make the most of the fantastic features offered on the Cat Backhoe Loader.

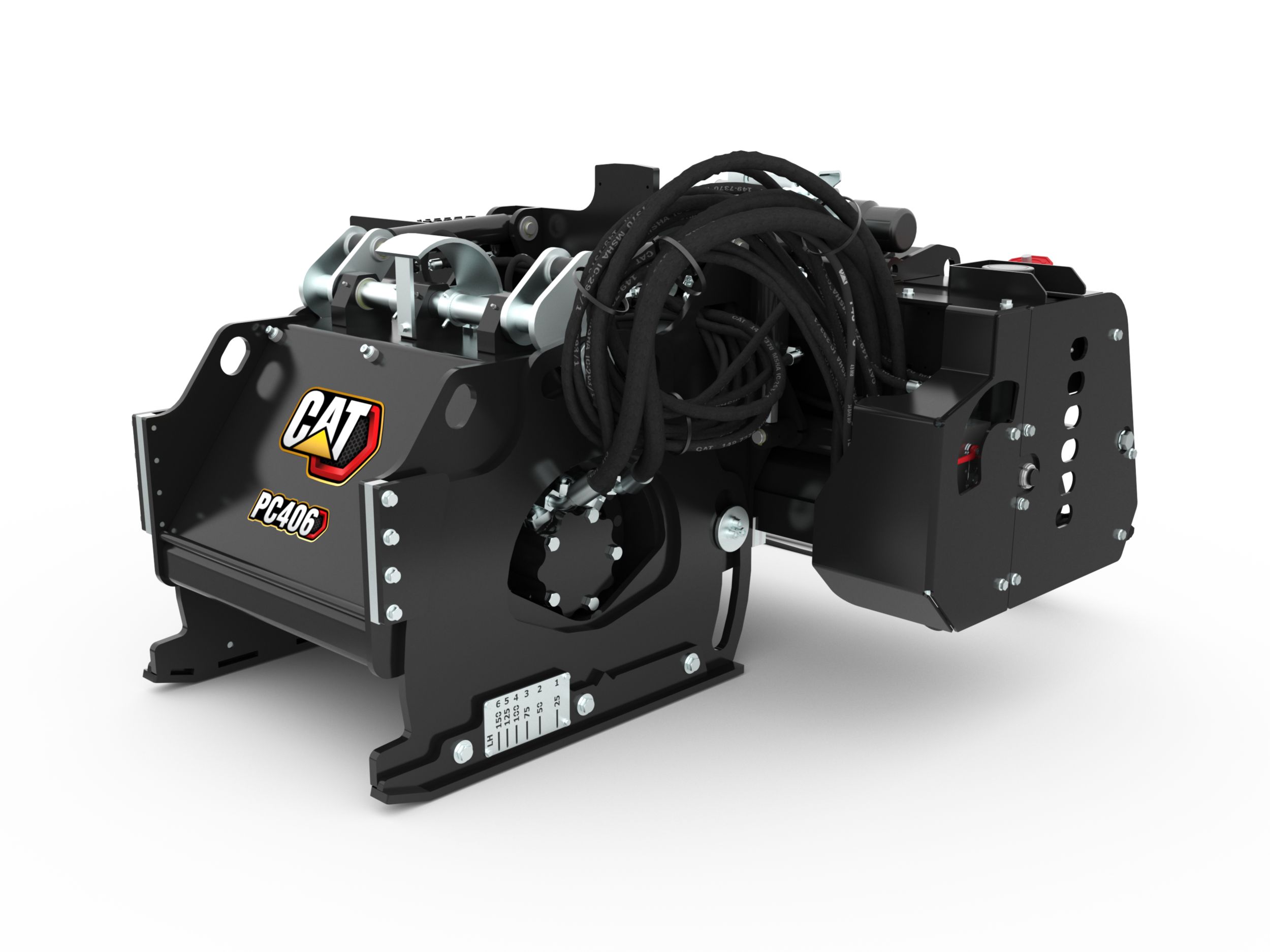

Work Tools – A solution for every job.

Loader – Loader Buckets

General Purpose (1.05 m³), Multi Purpose (1.0 m³) and Multi Purpose with Fork Brackets (1.0 m³) are all available on the 426F2 and are all fitted with Bolt-on Teeth.

Backhoe – Excavating Buckets

Cat Work tools provide a range of buckets in various sizes making it easy to find the correct bucket for your application

- Standard Duty

- Heavy Duty

- High Capacity

- Rock

- Ditching

Backhoe – Other Available Tools for Backhoe

- Cold Planers

- Hammers

- Augers

- Vibratory Compaction Plates

Backhoe – Backhoe Quick Coupler

A mechanical coupler is available for the 426F2 making changing rear work tools easy and safe.

Standard Equipment

-

CAB

- Canopy, Base

- Cab ROPS and FOPS are standard. ROPS (Roll Over Protective Structure) offered by Caterpillar for this machine meets ROPS criteria ISO 3471:2008 and FOPS (Falling Objects Protective Structure) criteria ISO 3449:2005

-

TIRES/STEERING/BRAKES

- Two Wheel Drive

- 100% Differential Lock

- Hydraulic Boosted Brakes (dual pedals)

- Tires 12-16.5 (Front) – 2WD

- Tires 12.5/80-18 (Front) – AWD

- Tires 16.9-28 Rear

-

ENGINE/TRANSMISSION

- Battery 750 CCA, Maintenance Free (standard)

- Engine 68.5 kW (93 hp) Cat 3054C

- Transmission Neutralizer

- Transmission, 4 Speed Manual

-

INPUT

- Controls, Mechanical Lever

- Power Steering, Hydrostatic

-

OTHER ATTACHMENTS

- Tool Storage Box

- Transport Tie – Downs

-

GUARDS

- Loader Safety Brace

-

BOOM STICKS AND LINKAGES – BACKHOE

- Stick Standard

- Transport Lock, Swing

- Transport Lock, Boom

-

HYDRAULICS

- Hydraulic Pump (132 L/min)

- Side Shift Lock (electro-hydraulic)

- Hydraulic Oil Cooler

-

HYDRAULICS – LOADER

- Loader Kickout, Float

- Parallel Lift

-

ELECTRICAL

- Reversing Alarm

-

CAB OPTIONS – CANOPY, BASE

- Beacon Socket (×2)

- Cup Holder

- Differential Lock Button on Loader Control

- Removable floor mat

- Front Headlights

- Fully Adjustable Halogen Work Lights (×6)

- Gauge Cluster

- Horn, Front

- Horn, Rear

- Internal Power Socket (×2)

- Rear Tail Lights

- Left Hand Storage Console

- Safety Lock, Transmission

- Seat, Vinyl with Mechanical Suspension

- Self-Cancelling Directional Indicator

-

CAB OPTIONS – CANOPY, PLUS

- Beacon Socket (×2)

- Cup Holder

- Differential Lock Button on Loader Control

- Removable floor mat

- Front Headlights

- Fully Adjustable Halogen Work Lights (×6)

- Cab, Part Glazed (front window)

- Gauge Cluster

- Horn, Front

- Horn, Rear

- Internal Power Socket (×2)

- Rear Tail Lights

- Left Hand Storage Console

- Safety Lock, Transmission

- Seat, Vinyl with Mechanical Suspension

- Self-Cancelling Directional Indicator

- Window Wash Wipers, Front

-

CAB OPTIONS – CAB, STANDARD

- Beacon Socket (×2)

- Cup Holder

- Differential Lock Button on Loader Control

- Removable floor mat

- Front and Rear Side Opening Windows

- Front Headlights

- Fully Adjustable Halogen Work Lights (×6)

- Cab, Fully Glazed

- Gauge Cluster

- Horn, Front

- Horn, Rear

- Internal Power Socket (×2)Internal Power Socket (×2)

- Rear Tail Lights

- Left and Right opening Doors

- Left Hand Storage Console

- Safety Lock, Transmission

- Seat, Fabric with Mechanical Suspension

- Self-Cancelling Directional Indicator

- Window Wash Wipers, Rear

- Window Wash Wipers, Front

-

CAB OPTIONS – CAB, STANDARD PLUS

- Beacon Socket (×2)

- Cup Holder

- Differential Lock Button on Loader Control

- Removable floor mat

- Front and Rear Side Opening Windows

- Front Headlights

- Fully Adjustable Halogen Work Lights (×6)

- Cab, Fully Glazed

- Gauge Cluster

- Horn, Front

- Horn, Rear

- Internal Power Socket (×2)

- Rear Tail Lights

- Left and Right opening Doors

- Left Hand Storage Console

- Safety Lock, Transmission

- Seat, Fabric with Mechanical Suspension

- Self-Cancelling Directional Indicator

- Steering Wheel Column, Tilt Adjustment

- Window Wash Wipers, Rear

- Window Wash Wipers, Front

Optional Equipment

-

CAB

- Canopy, Plus

- Cab, Standard

- Cab, Standard Plus

-

TIRES/STEERING/BRAKES

- All Wheel Drive

- Tires 18.4-26 Rear

-

ENGINE/TRANSMISSION

- Battery 750 CCA, Maintenance Free (heavy duty)

- Engine Block Heater

-

OTHER ATTACHMENTS

- Counterweight, 115 kg

- Counterweight, 240 kg

- Counterweight, 460 kg

- Front Fenders

- Street Pads, Stabilizers

- Rear Licence Plate Holder and Light

-

GUARDS

- Guard, Teeth (GP/MP)

- Guard, Driveshaft

- Guard, Tail Lights

-

BOOM STICKS AND LINKAGES – BACKHOE

- Stick Extending

-

HYDRAULICS

- Hydraulic Auxiliary Quick Disconnects

-

HYDRAULICS – BACKHOE

- Hydraulic Lines, 1-Way

- Hydraulic Lines, 2-Way (with E-Stick)

-

HYDRAULICS – LOADER

- Ride Control

-

ELECTRICAL

- Product Link, Cellular

- Product Link, Satellite

- Beacon, Strobe

- Beacon, Standard

-

CAB OPTIONS – CANOPY, BASE

- Face Fan

-

CAB OPTIONS – CANOPY, PLUS

- Face Fan

-

CAB OPTIONS – CAB, STANDARD

- Air Conditioning

- Face Fan

- Full Width Perforated Sun Visor

-

CAB OPTIONS – CAB, STANDARD PLUS

- Air Conditioning

- Face Fan

- Full Width Perforated Sun Visor